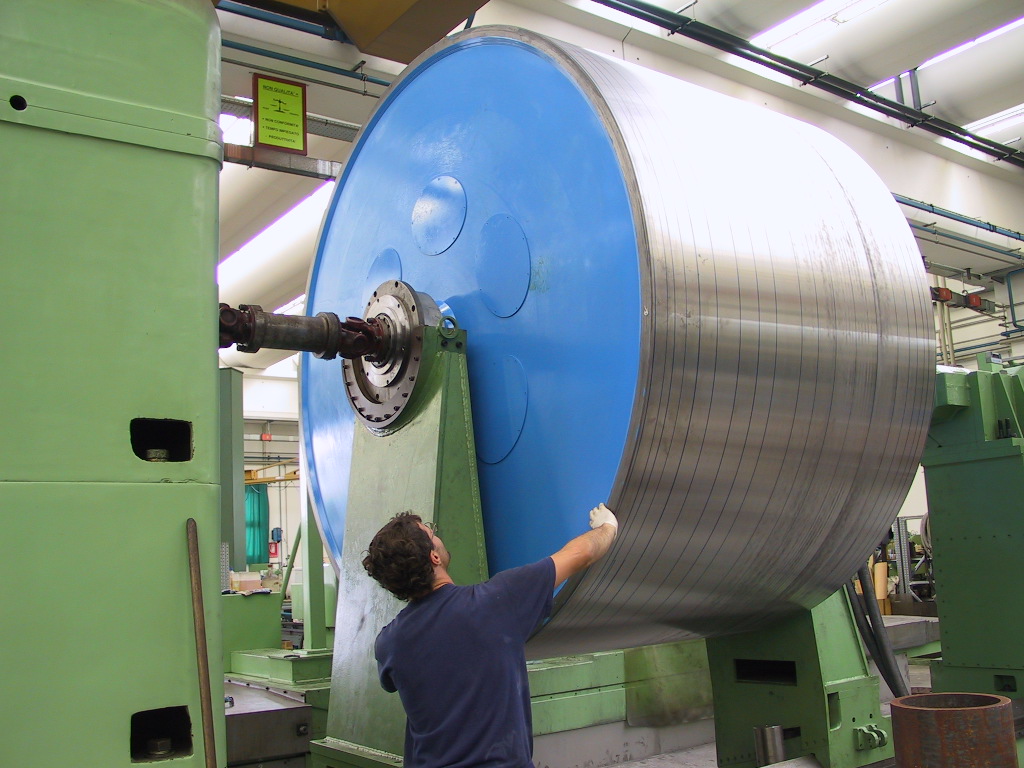

Thanks to the experience and know-how accumulated in forty years of activity in mechanical turning and milling, we produce finished mechanical parts of different complexities, using CNC machinery, machining centers, traditional and auxiliary machinery that meet the standards higher: maximum precision and particularity for each single piece produced.

We mainly work with steels, tempered steels, stainless steels (AISI), aluminum, copper, brass, plastics, composite materials and carbon.

We are able to coat the cylinders with various materials and / or chemical processes, such as chromium, nickel, hard anodic oxidation, plasma coating, tungsten carbide and other coatings on the market. Pam Rollers Factory relies on a large team of selected suppliers thanks to which we expand the range of our solutions.

Research of materials and product development, production automation, testing and control departments are constantly committed to maintaining the quality standards of products and customer services that are increasingly customized to measure.

Relying on Pam Rollers Factory allows you to have an expert and reliable partner with whom to find the best design solution and experiment with new innovative solutions.

Some of our products available:

- Steel, aluminum, carbon cylinders;

- Clichè holder cylinders;

- Sleeve cylinders;

- Return or contact cylinders;

- Idle rollers;

- Cutting cylinders;

- Blade holder cylinders and hardened counter-knives;

- Rolls for calenders;

- Spiral heated dosing cylinders;

- Spreading cylinders;

- Grinding cylinders;

- Back pressure drum cylinders up to diam. 3800 mm;

- Gears of metal or plastics;

- Gears for drum cylinders up to diam. 3800 mm;

- Special cylinders on customer request;

- Sleeve clichè;

- Sleeve Anilox Shells.

Upon specific customer request, we are able to supply cylinders with rubber linings or chromed cylinders.

By means of a dynamic technical office, CNC machines with high technological content and effective quality control for the entire duration of the production process, the Pam Rollers Factory carries out complete orders based on the customer’s design, creating both single and assembled pieces, used in particular in printing, paper, textile, plastic and converting sectors. At the customer’s request, we also carry out heat or surface treatments and take care of the final packaging.